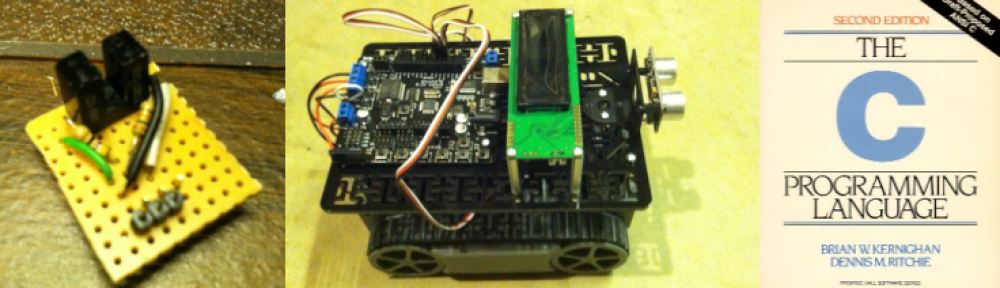

This post is more suited to Halloween then the coming Yule, but I finally got around to writing it, and besides, as I write this, there’s only 327 days left to next Halloween! There are several options for controlling animated props, including prop controllers specifically designed for this purpose. A recent addition to the market is the MonsterShield, an Arduino-based prop controller with open source code you can modify. I haven’t tried one out, but thought it was work a mention. In my props, I just use a handy micro-controllers, such as an Arduino, along with sensors such as a PIR. The PIR (or pressure mat, or whatever sensor you choose) sends a signal to the microcontroller when it detects someone, and then your microcontroller can trigger a whole sequence of pre-programmed actions. I had two such props in my Halloween display this year. The first is a classic “Monster in a Box“. I use a PIR sensor to detect when someone comes near. When this happens,a Teensy sends out an output to a Power Switch Tail to turn on the power to a wall wart that delivers 12V power to the windshield wiper motor, as well as to a green light inside the box. I use a Power Switch Tail so that I don’t have to worry about any safety issues dealing with house current directly. The motor sequence has several stops and stop in it, of differing lengths, so that the action is more natural. After it triggers, there’s a dead time, so that it doesn’t keep restarting while trick-or-treaters are standing in front watching it.

The other prop where I use a PIR and an Arduino is my scarecrow skeletons, who do a little talking and singing routine when triggered. Here, an Arduino controls two Cowlacious audio boards that in turn drive the servo boards that control the jaw servo and lights in the skulls (also from Cowlacious). I’ve had the audio boards for some time. They work fine, and have a wide host of control options (including the ability to be triggered directly from a PIR). However if I was remaking this prop, I’d probably just wire up some really cheap mp3 players. The video shows the two skeletons doing their routine. Sorry for the quality, my video editor is refusing to save the edited version.